In the heart of Jefferson County, Pennsylvania, a simple yet powerful initiative is transforming how a community thinks about waste, resources, and giving back. Glass4Good™, an O-I glass recycling program rooted in circularity and hometown pride, is turning recycled glass into tangible impact, one glass bottle at a time.

Of O-I’s 20 glass recycling community programs in the U.S., the team at the Brockway-Crenshaw plants have grown their Glass4Good™ into an expansive community partnership. What sets it apart isn’t just the volume of recycled glass collected, but the way employees and the community have embraced it.

“We take glass that’s either donated through the community or by local businesses,” says Ryan Fox, Brockway-Crenshaw Plant LEHR Quality Controller. “We take that, and the proceeds and everything, go back to our community.”

That spirit of giving has become the central thread of the program.

Glass4Good: Built by Employees, Powered by Community

While Glass4Good™ originated as a corporate sustainability initiative, it found strong roots in Brockway and Crenshaw. According to Danielle Brickner, O-I Sustainability Collaboration Specialist, the program’s expansion into the community happened naturally.

“Jefferson County already had a robust recycling system, and we had a solution for their glass—ensuring it remained in the manufacturing stream,” Brickner explains.

“Glass4Good™ was started by a small group of O-I employees from our headquarters, and Brockway-Crenshaw was an easy expansion opportunity because they already had the means to collect glass.”

Since 2021, Jefferson County has operated 14 recycling collection sites that now bring their recycled glass bottles and jars to the O-I plant, along with new sites in three neighboring counties.

And what’s really impressive is that the Brockway-Crenshaw leadership team didn’t wait for direction. Instead, they created their own system for collecting glass packaging from local bars and restaurants.

So how does this system work?

Every Friday, a dedicated team of employees uses a truck designated for the recycling program to pick up glass from participating businesses. The collected glass is brought back to the plant’s Glass4Good™ bunker, stored until a shipment of clean cullet (the industry term for recycled glass) is ready, and then backhauled to a glass processor for cleaning, sorting, and ultimately returned to production.

“The Brockway-Crenshaw teams have really taken ownership of the program,” says Brickner. “They’ve gotten creative to collect more glass, be present in the community, and educate others about glass recycling.”

The result is a thriving, self-sustained operation that reflects the best of what local collaboration can achieve.

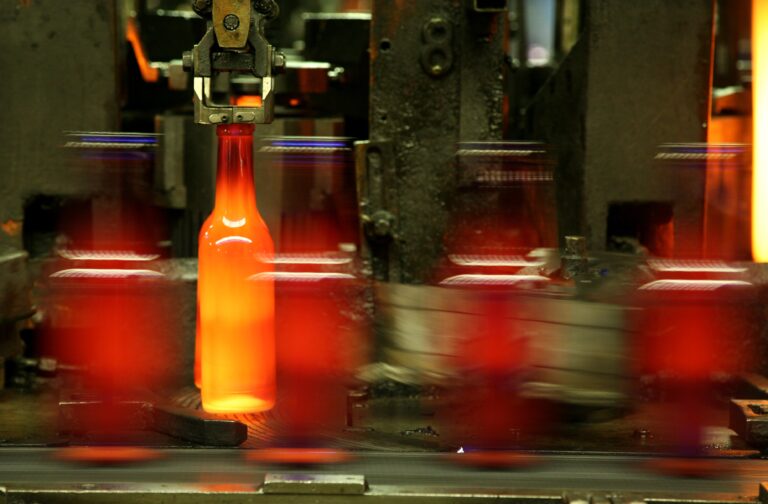

The Power of Glass in a Circular System

Glass is a uniquely circular material that can be recycled endlessly without losing quality. This means that glass bottles collected through Glass4Good™ can be remade into new bottles again and again, reducing the need for raw materials and the energy required to create them.

It’s the simplicity of glass that makes it so powerful as a packaging material. Glass is made of four simple ingredients: sand, soda ash, limestone, and recycled glass.

As Brickner comments, “By using recycled glass in our manufacturing process, we conserve raw materials, reduce greenhouse gas emissions, lower energy consumption, and support local job creation. Glass4Good™ takes that impact even further with charitable donations.”

On the operational side, using cullet instead of virgin materials makes the glass manufacturing process more efficient and sustainable, helping O-I produce high-quality, sustainable glass packaging.

You can see how O-I’s glass recycling program creates positive impact for the planet and local communities.

From Glass Plant Operations to Community Impact

The Brockway-Crenshaw team’s efforts don’t just keep glass in the manufacturing loop; they also generate real benefits for the people they know and care about in the community. Since its inception in 2021, the Jefferson County Glass4Good™ program has generated over $25,000 in donations to local organizations, including the Brockway Area School District.

The school district uses these funds to support students and teachers. In particular, the donations help cover costs for dual enrollment programs with Mount Aloysius College and BC3, as well as Advanced Placement exam fees. As a result, students have the opportunity to graduate high school with a semester (or even a full year) of college credits already completed.

That type of community investment underscores the “for good” in Glass4Good™.

A Ripple Effect of Pride and Purpose

What began as a corporate sustainability initiative has evolved into a deeply personal mission for the employees who make it happen.

Employees not only see their contributions come full circle, but they also bring their own recyclables from home.

As Brielle Johnston, Mold Repair Journeyman at the Brockway-Crenshaw Plant, states, “When I buy something off the shelf at the store — pasta sauce, pickles — when I’m done with that jar, I’m not just sticking it in a recycle bin on the side of the street and hoping it gets recycled. I get to bring it directly to work and see it get back into production.”

You can tell there’s a sense of ownership and pride in the process. That passion continues to fuel the glass recycling momentum, proving that sustainability thrives when communities and companies work together.

Glass Recycling Model for the Future

Glass4Good™ at Brockway-Crenshaw is more than a recycling program; it’s a blueprint for community-driven action that supports O-I in achieving its 2030 sustainability goals.

It demonstrates how circularity can extend beyond manufacturing to create real, measurable impact, supporting schools, empowering employees, and reducing waste.

From the plant floor to local classrooms, Glass4Good™ is proof that sustainability isn’t just about materials; it’s about more. It’s about people coming together to take action for the greater good.